Advanced Exposure Technique

Motivation:

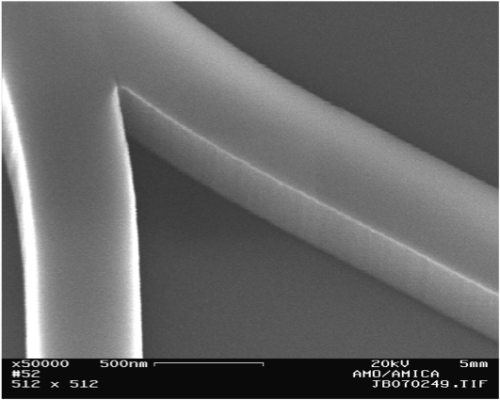

E-Beam lithography can achieve very high resolution and low line-edge roughness by using a small beam size (low beam current). Consequently, this leads to small beam-step sizes and very long exposure times for larger areas to be written. In contrast, large beam currents are needed for fast writing, but this results in large beam sizes and large beam-step sizes, leading to lower resolution and larger LER.

Solution:

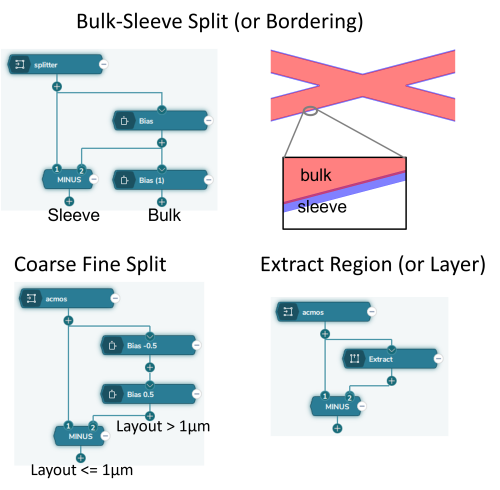

The BEAMER data-preparation functions allow to split the layout into one high accuracy exposure and one exposure with high throughput. Depending on the application, BEAMER allows to easily perform „Bulk & Sleeve“ splits, „Coarse & Fine“ splits, filter the layout by feature size or area or allow manual extraction of critical features. Then the data is converted for a fine beam high accuracy exposure and a large beam high throughput exposure. BEAMER’s Proximity Effect Correction is able to take into account both exposures and further shortens the exposure time by adjusting the doses to the minimum required. In addition, intelligent multi-exposure techniques enable better litho quality in terms of increased resolution and accuracy.

The combination of those techniques enables exposure time reduction from several days to a just few hours while maintaining high resolution and pattern quality.